Learn how nanobubble technology helped horticulture growers improve plant health and yields.

Learn how Big Tex Urban Farms improved growing conditions and reduced crop loss with nanobubble technology for their hydroponic leafy green crops.

Aardbeienkwekerij Penninx, a Dutch strawberry nursery in the Netherlands, achieved lower disease counts, better root development, higher fruit weight, and increased yields after deploying Moleaer's nanobubble technology in their greenhouse.

Nanobubble-enriched irrigation water helped this Italian flower exporter improve crop health, reduce biofilm and reduce chemical usage. Learn how sustainable nanobubble technology can help improve your horticulture operations and crop yield.

Learn more about how pepper grower Rob Moors improved roots health and development increasing dissolved oxygen levels across all the greenhouses. Watch the video from Moleaer's partner in the Netherlands, Royal Brinkman.

Henry Gordon-Smith, CEO of Agritecture, interviews Richard Smits, Manager at one of the largest basil and other herbs growers in the Netherlands, who has been using nanobubbles in their hydroponic system for a number of years.

Learn how Big Tex Urban Farms improved growing conditions and reduced crop loss with nanobubble technology for their hydroponic leafy green crops.

Aardbeienkwekerij Penninx, a Dutch strawberry nursery in the Netherlands, achieved lower disease counts, better root development, higher fruit weight, and increased yields after deploying Moleaer's nanobubble technology in their greenhouse.

Nanobubble-enriched irrigation water helped this Italian flower exporter improve crop health, reduce biofilm and reduce chemical usage. Learn how sustainable nanobubble technology can help improve your horticulture operations and crop yield.

Learn more about how pepper grower Rob Moors improved roots health and development increasing dissolved oxygen levels across all the greenhouses. Watch the video from Moleaer's partner in the Netherlands, Royal Brinkman.

Henry Gordon-Smith, CEO of Agritecture, interviews Richard Smits, Manager at one of the largest basil and other herbs growers in the Netherlands, who has been using nanobubbles in their hydroponic system for a number of years.

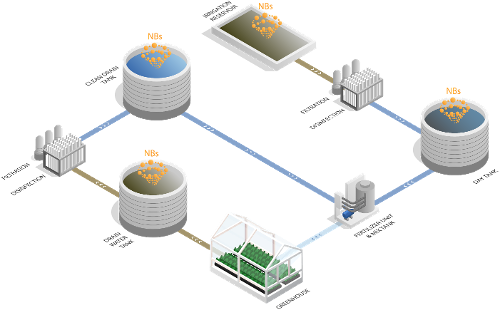

Chemical-free nanobubble technology can be installed to treat greenhouse irrigation reservoirs or to recirculate water in day and drain tanks. Moleaer’s patented nanobubble generators were designed and built using our engineering team’s extensive experience with greenhouse and indoor growing applications. They’re easy to integrate, install, and maintain — without overhauling your irrigation system. Leverage user interfaces and monitoring to ensure your system is performing at its peak.

Our Products

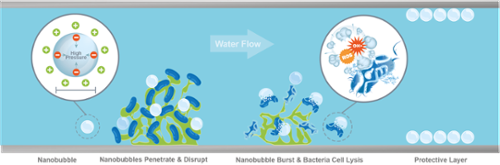

Improve the cleanliness of your irrigation system while simultaneously enhancing plant growing conditions leading to better plant and root health. Proven to prevent water-borne pathogens and biofilm, nanobubbles enable plants to become more resilient to environmental, heat and water stress and significantly reduce root disease occurrence. Greenhouses that install Moleaer’s nanobubble generators have seen improved plant vigor, better crop yields and reduced chemical applications within months of installation.

Nanobubbles enhance a wide range of growing methods including hydroponics, deep water culture (DWC), nutrient film technique (NFT), aquaponics, recirculation and drip systems. Moleaer’s nanobubble generators have optional onboard oxygen or can be connected to an external oxygen tank to increase oxygen potency, leading to elevated levels of dissolved oxygen. More oxygen at the root zone promotes better root development and plant growth resulting in improved crop quality.

Watch the webinarLeafy greens are commonly grown in greenhouses in hydroponic systems where the roots are grown directly in water, therefore, waterborne pathogens such as Pythium and Phytopthora and biofilm are a widespread concern. Traditionally, growers must use chemical cleaners and pesticides to keep diseases at bay, however, Moleaer’s chemical-free nanobubble technology is now a more cost-effective and environmentally friendly option.

Growers of leafy greens like Rebel Farms, Revol Greens and BuxMont have experienced the benefits of nanobubble technology with reduced pathogens, better root development and improved crop quality. From reducing pesticides and cleaning products to higher quality yields, these leafy green growers are simultaneously reducing their costs and environmental impact.

Many tomato greenhouse growers are seeking innovative technologies to improve the efficiency and sustainability of their operations. From AI to nanobubble technology, growers can now experience better quality crops while reducing their pesticide applications, energy usage and labor.

Tomato growers like Gebroeders Koot in the Netherlands, the “cradle” of greenhouse technology, have seen improved root development from higher dissolved oxygen levels and reduced root pathogens in their greenhouse operations after deploying nanobubble technology. Even in the warmer months, when it’s harder to sustain healthier roots, Gebroeders Koot was able to maintain healthy root growth resulting in reduced crop losses.

Additionally, NovaCropControl, an industry-leading research and test center in the Netherlands, produced a study using Moleaer’s technology for tomato greenhouse crops. They found that nanobubbles increased nutrient uptake efficiency and water use efficiency as well as reduced disease.

The most common berries grown in greenhouses include strawberries, raspberries and blackberries. As with most greenhouse crops, root diseases like Pythium and Phytophthora are common and can greatly impact the bottom line for berry growers.

Delphy Research Institute in the Netherlands conducted trials on nanobubble technology for greenhouse strawberries and found that oxygen nanobubble irrigation water produced healthier root mass, lower root disease occurrences and higher yields. This was attributed to oxygen nanobubbles increasing the dissolved oxygen levels to an average of 30 mg/L which created a more aerobic environment, and the mild oxidative effect of nanobubbles that suppressed and prevented pathogens and biofilm.

Ornamental growers produce cut flowers, landscape plants, indoor plants and more for garden centers and nurseries as well as wholesale clients. Quality crops with healthy root systems are key to their success and keeping crop cycles consistent can improve their deliverability and strict deadlines.

Harster Greenhouses, an ornamental grower in Canada, was able to improve their crop cycle consistency while reducing it from 8 to 6 weeks. They were also to improve the quality of the crops, seeing reduced wilt after long transport periods to their customers. Even better, they were able to reduce fertilizers by 10%, allowing them to save on the bottom line.

“When we look at working with technology providers, having those knowledgeable team members on their side to work with my team members has been invaluable,” she said. “The nanobubble technology is something that I have been very intrigued with… [Moleaer] has already been physically on site three times — with initial recommendations, at install, and again at midtrial — working closely with the

team as they work through small-scale trials and then scale up.”

President and General Manager, Traders Hill Farm

“We are thrilled with the results we have seen at our Revol Greens greenhouse since installing the Bloom nanobubble generator. The ability of the system to help manage Pythium in water while promoting plant growth is substantial to our bottom line. The on-average 15% improvement in our yields was very surprising. This technology has demonstrated to us that it should and will be standardized into our current facility and the 3-hectare expansion we are doing this year.”

Head Grower, Revol Greens

“We strongly believe that nanobubbles, in combination with soil amendments and microbes, such as mycorrhiza, have improved the soil structure, which can be seen in improved and new root development, better water infiltration and water retention. We expect to continue our orchard improvement through irrigation efficiency in order to face these drought conditions."

Production Manager, Noble Fruit