Moleaer’s oxygen nanobubble technology is a sustainable and chemical-free solution for outdoor agriculture and controlled-environmental cultivation processes. In this video, you’ll learn about two of our products, the Neo and the Clear nanobubble generators, that easily integrate into your existing irrigation and fertigation systems to improve water quality, increase crop yields, control biofilm and pathogens, mitigate common soil/substrate issues and more.

Two growers in Chile improved their crops using Moleaer's nanobubble technology. Nanobubbles helped the cherry grower improve root zone conditions that led to better fruit development. The avocado grower installed nanobubble technology on their irrigation reservoir to control algae. They achieved reduce algae growth and better water quality, which ultimately improved plant growth and fruit production.

Watch the video to learn more.

Learn more by watching this webinar with Malvern Panalytical and Moleaer.

Two growers in Chile improved their crops using Moleaer's nanobubble technology. Nanobubbles helped the cherry grower improve root zone conditions that led to better fruit development. The avocado grower installed nanobubble technology on their irrigation reservoir to control algae. They achieved reduce algae growth and better water quality, which ultimately improved plant growth and fruit production.

Watch the video to learn more.

Learn more by downloading the berry eBook.

Moleaer’s oxygen nanobubble technology is a sustainable and chemical-free solution for outdoor agriculture and controlled-environmental cultivation processes. In this video, you’ll learn about two of our products, the Neo and the Clear nanobubble generators, that easily integrate into your existing irrigation and fertigation systems to improve water quality, increase crop yields, control biofilm and pathogens, mitigate common soil/substrate issues and more.

Two growers in Chile improved their crops using Moleaer's nanobubble technology. Nanobubbles helped the cherry grower improve root zone conditions that led to better fruit development. The avocado grower installed nanobubble technology on their irrigation reservoir to control algae. They achieved reduce algae growth and better water quality, which ultimately improved plant growth and fruit production.

Watch the video to learn more.

Learn more by watching this webinar with Malvern Panalytical and Moleaer.

Two growers in Chile improved their crops using Moleaer's nanobubble technology. Nanobubbles helped the cherry grower improve root zone conditions that led to better fruit development. The avocado grower installed nanobubble technology on their irrigation reservoir to control algae. They achieved reduce algae growth and better water quality, which ultimately improved plant growth and fruit production.

Watch the video to learn more.

Learn more by downloading the berry eBook.

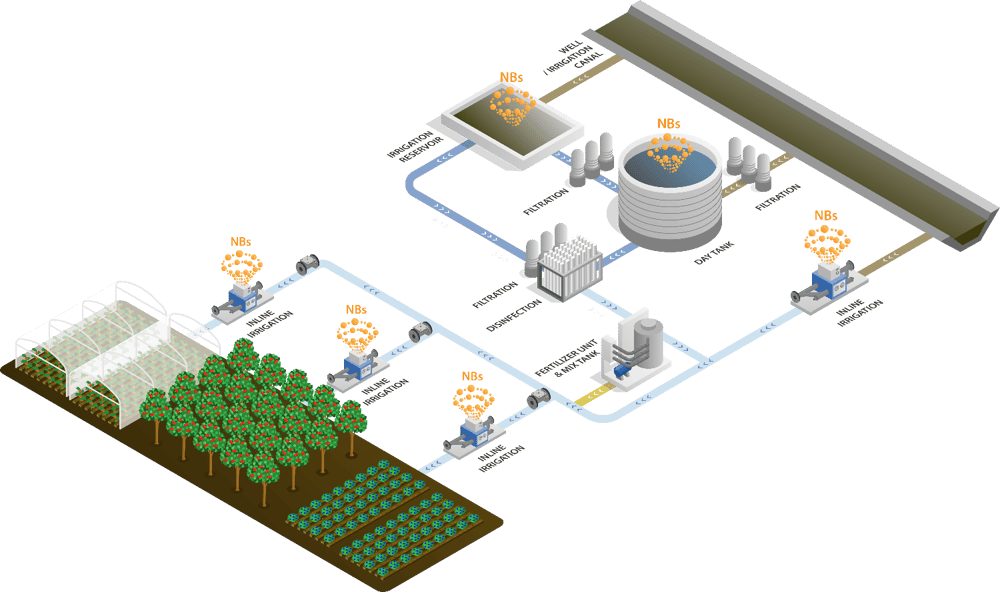

Chemical-free nanobubble technology can be installed to treat source water from wells, canals, reservoirs and basins to reduce algae and pathogen growth, improve water quality, and reduce the use of chemicals and pesticides. Nanobubble generators can also be installed on day tanks or inline before your valve zone or irrigation sector. Moleaer’s patented nanobubble generators are easy to integrate, install, and maintain — without overhauling your irrigation system.

Our Products

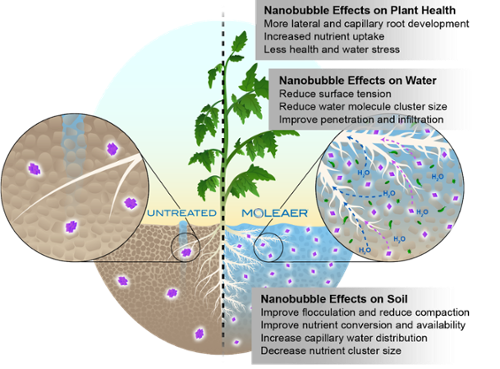

Plants thrive in soils with good structure, ample microbial activity and available nutrients to develop healthy root systems and produce quality crops. However, farmers worldwide face challenging soil conditions from drought stress, exhaustion and poor-quality irrigation water. Nanobubbles have been scientifically proven as a chemical-free solution to improve soil conditions for growers, from reducing soil compaction to increasing soil aeration, nutrient availability and uptake efficiency.

Download the Brochure

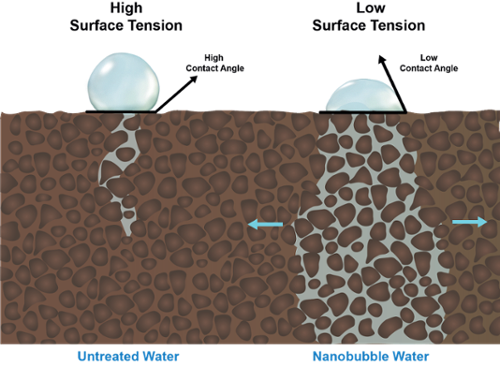

Scientific research and independent case studies show that nanobubbles increase soil flocculation, reduce compaction and increase capillary water distribution. Nanobubbles reduce the surface tension of water, improve water infiltration and percolation through the soil profile, improve salt leaching and get more water and nutrients to the root zone where plants need it. Nanobubbles decrease the size of nutrient clusters and raise ionic mobility aiding in increased nutrient availability and uptake efficiency. Plants grown with nanobubble irrigation water have a higher resilience against stress factors, improving crop quality and reducing crop loss for farmers.

More About Soil HealthAvocado trees are particularly susceptible to root asphyxia, or the drowning of plant roots. Most of the world’s avocado plants are grown in clayey soil conditions with high water holding capacity. Nanobubbles help farmers address issues with clayey soils in two ways. First, nanobubbles reduce the surface tension of water improving its penetration and infiltration in soil. Second, nanobubbles increase soil flocculation, the aggregation of clay particles, which improves soil structure and infiltration.

Kapicua Research Center conducted a study on avocados grown in Chile. They installed a Moleaer nanobubble generator in an avocado orchard using drip irrigation. After one season, Kapicua saw improved vegetative tree growth and productivity and a 40% increase in fruit size. This was attributed to increased dissolved oxygen levels in the irrigation water and better infiltration through the clayey soil to the root zone.

Berries of all types are grown outdoors in soil and substrates. Blueberries require highly acidic soils, so they are often grown outdoors in pots with soil substrates. Whether grown in pots or not, berries, like blueberries, blackberries, raspberries and strawberries, require good quality irrigation water to produce high-quality fruits.

Irrigation water supersaturated with nanobubbles improves root development, boosts plant health and enhances soil structure for growing better crops. One blueberry grower in Chile deployed Moleaer’s nanobubble technology on their fertigation tank to improve growing conditions. They saw a 20% reduction in soil compaction that resulted in increased new shoot growth, improved fruit production and increased beneficial microbial activity in the soil.

Citrus orchards consist of oranges, lemons, grapefruits, pomelos and limes, with oranges accounting for more than half the global citrus output. Many citrus growers are facing increased demand amid the threat of pests and disease, drought concerns and labor shortages.

Nanobubbles prevent root diseases from developing and spreading by increasing aerobic water conditions and making the environment less favorable to pathogens. Additionally, nanobubbles prevent and control biofilm, which is pervasive on all surfaces that come in contact with water and can harbor pathogens. Growers see improved irrigation system hygiene enabling them to reduce the application of cleaning products and chemicals like hydrogen peroxide and chlorine. Citrus growers can greatly benefit from nanobubble technology in their orchards.

Moleaer’s nanobubble technology does two things: supersaturates irrigation water with dissolved oxygen and injects hundreds of millions of electrochemically charged nanobubbles that alter the properties of water to deliver multiple benefits.

Increased dissolved oxygen levels maximize oxygen utilization by plants and beneficial microbes in the rhizosphere, promoting healthy root development and improving plants’ resilience to environmental stressors such as drought and heat.

High concentrations of negatively charged nanobubbles reduce the surface tension of water and improve infiltration of soils and substrates as well as improve the capillary action of dissolved nutrients – a low-cost, synergistic input to reduce soil compaction and high salinity.

Nanobubbles also produce a natural, mild oxidant when they encounter contaminants in the water, reducing water-borne pathogens and algae. Their hard, stable shell allows them to abrade biofilm and scale from irrigation systems and coat piping walls in a thick layer to limit new accumulation – improving system hygiene and reducing treatment costs. These are just a few of the benefits nanobubbles offer growers.

Using nanobubble technology in farming has shown many benefits that help achieve a successful crop, such as:

• Better root development

• Increased microbial activity and healthier microbiome (microbial life)

• Better uptake efficiency of nutrients and water

• Increased penetration and infiltration of water into soil and substrates

• Reduction in plant disease and improved crop resilience

• Less soil compaction

These are just a few of the many benefits of nanobubble technology to plant health that, together with adequate moisture and organic matter lead to resilient and healthy crops.

Yes, the use of nanobubbles has been proven to have a direct impact on improving soil health and function which has been shown to lead to the growth of healthy, more productive plants.

Nanobubbles reduce the surface tension of water, improving infiltration and penetration into soils and substrates, so more water is available to the plant roots. Also, nanobubbles improve soil and substrate wettability, helping to combat hydrophobic soils. Reduced compaction of soils is possible with nanobubbles through their ability to flocculate clay particles and improve soil structure.

Other benefits include increasing soil aeration, which helps improve the microbiome health and aid in the microbial activity that is essential for healthy soils.

All of these benefits help farmers improve soil health without the use of chemicals.

Moleaer's nanobubble generators are designed to be easy to install, maintain, and integrate into your existing system. Nanobubble generators are easily installed on irrigation day tanks, storage basins, irrigation reservoirs, or inline between the water supply and the crops.

There is no need for massive upgrades or a complete overhaul of your current system to implement this cost-effective nanobubble technology.

Nanobubble water can be used to improve the health of a wide range of crops and plants.

Recent commercial case studies have shown that nanobubble technology is effective among growers of:

• Avocados - These plants are normally grown in clay soils and as such are prone to suffer from asphyxiation due to lack of dissolved oxygen in the root zone, which can be prevented by using nanobubbles

• Berries - The proper growth of berries, such as the Blueberries being grown in Chile, requires acidic soils and good-quality irrigation water to produce healthy fruit. Using nanobubbles improves both the dissolved oxygen supply and the development of healthy soil structure to boost root development in the soil-covered parts of the plant and result in the growth of healthy plants

• Citrus - World citrus production of fruits, such as oranges, lemons, grapefruits, pomelos, and limes, is facing a serious threat due to the increase in pests that target these fruit trees. Using nanobubbles not only helps to prevent root disease but also creates a soil environment that is not favorable for the growth of pests thus helping farmers manage their crops without having to resort to pesticides and other potentially harmful chemicals

In addition to these crops, Moleaer has over 1000 agriculture and horticulture installations that cover crops across the world and has successfully applied nanobubbles to tomatoes, peppers, cucumbers, ornamental plants like Gerbera daisies, almonds, leafy greens and herbs, strawberries, hemp, and more. Check out our case studies page to learn more.

Although nanobubble technology is a relatively new process compared to traditional irrigation methods, there are many peer-reviewed journal articles highlighting the benefits of nanobubbles in agriculture and greenhouses. Moleaer compiled some on the resources page.

If you are looking for essential information on nanobubble water technology and advice on how you can install nanobubble generators in your irrigation system, Moleaer is one of the best sources of all the information you need.

You can also check out our blog for a variety of articles on how nanobubbles apply to agriculture.