Optimize Your Existing Wastewater Treatment Processes with Proven Technology & Expertise

Moleaer nanobubble technology combined with process and engineering expertise and global service support to solve your plant’s challenges and enhance treatment performance.

ABOUT

NanoShield by Moleaer

Get more from your existing wastewater treatment processes with Moleaer NanoShield. The NanoShield solution delivers comprehensive plant protection by integrating Moleaer’s proven process and integration engineering expertise with innovative nanobubble technology, supported by our dedicated Global Service Team. Real-world installations consistently demonstrate enhanced process stability, increased biogas production, and superior effluent quality, even during challenging conditions like industrial upsets. NanoShield doesn't just optimize your plant—it revolutionizes what's possible with sustainable, cost-effective process intensification.

Problems NanoShield Solves:

- Toxicity and upsets

- Odors, FOG and scum

- Capacity constraints

- High energy and chemical usage and costs

- Biogas production and quality

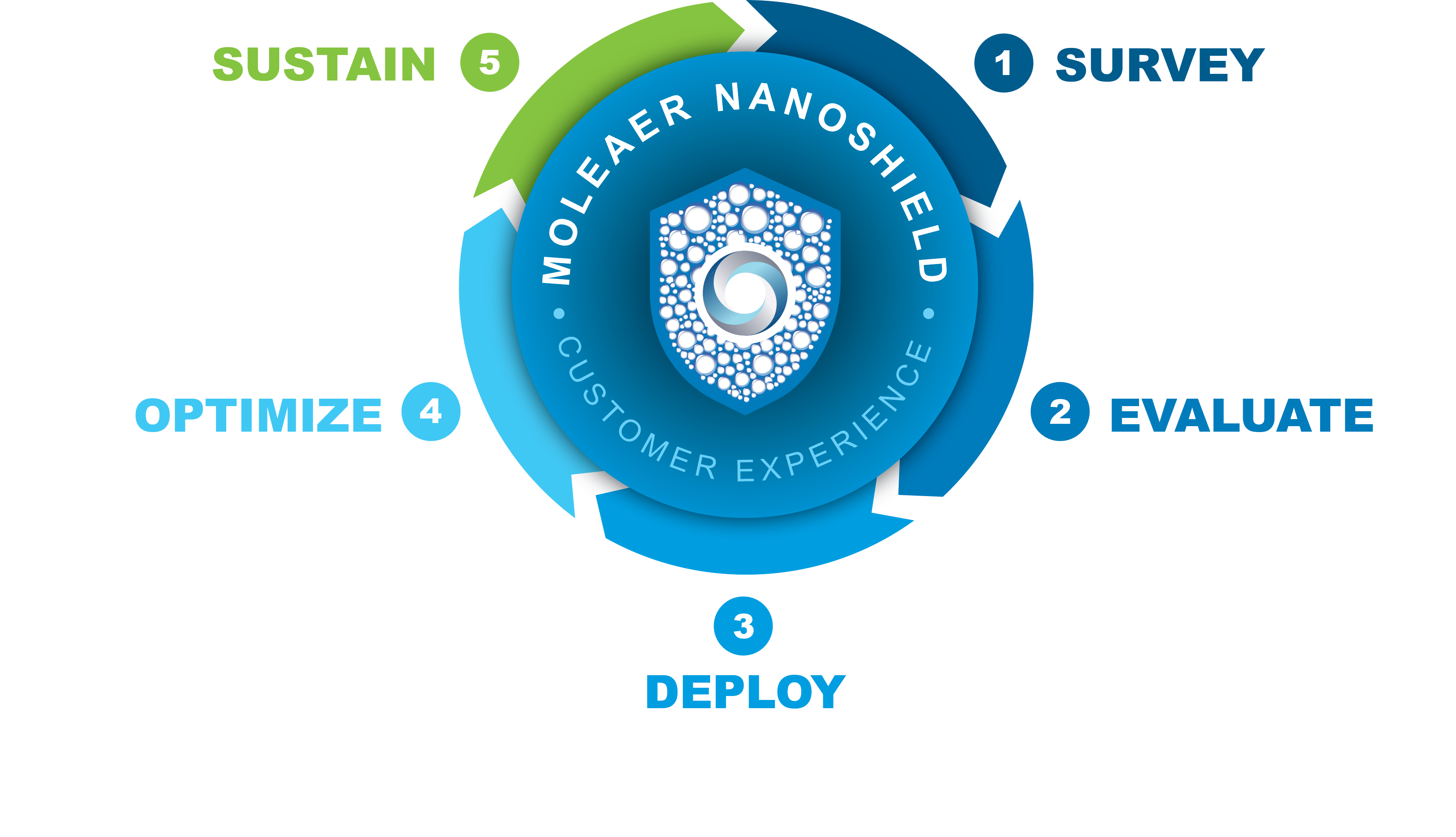

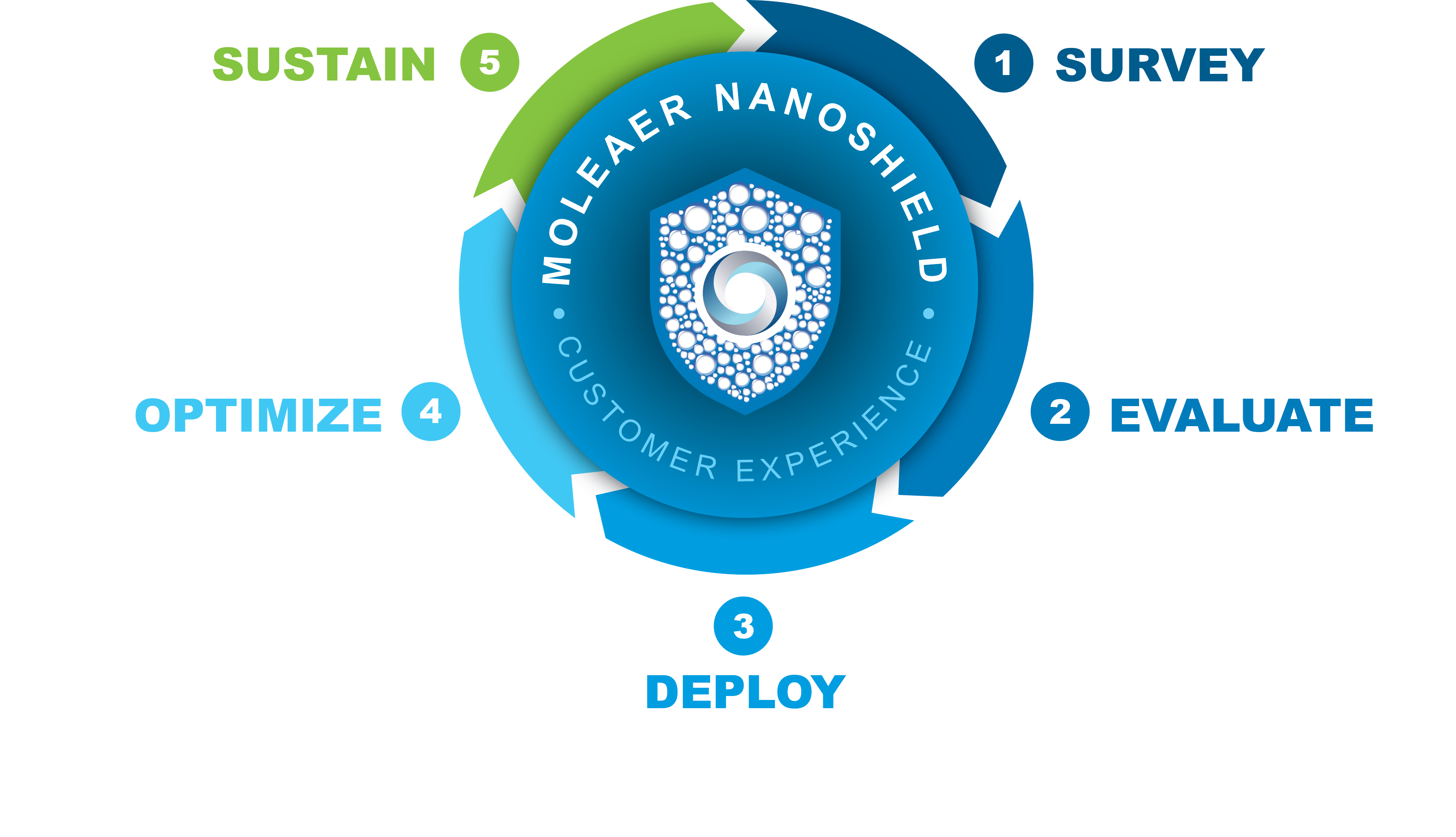

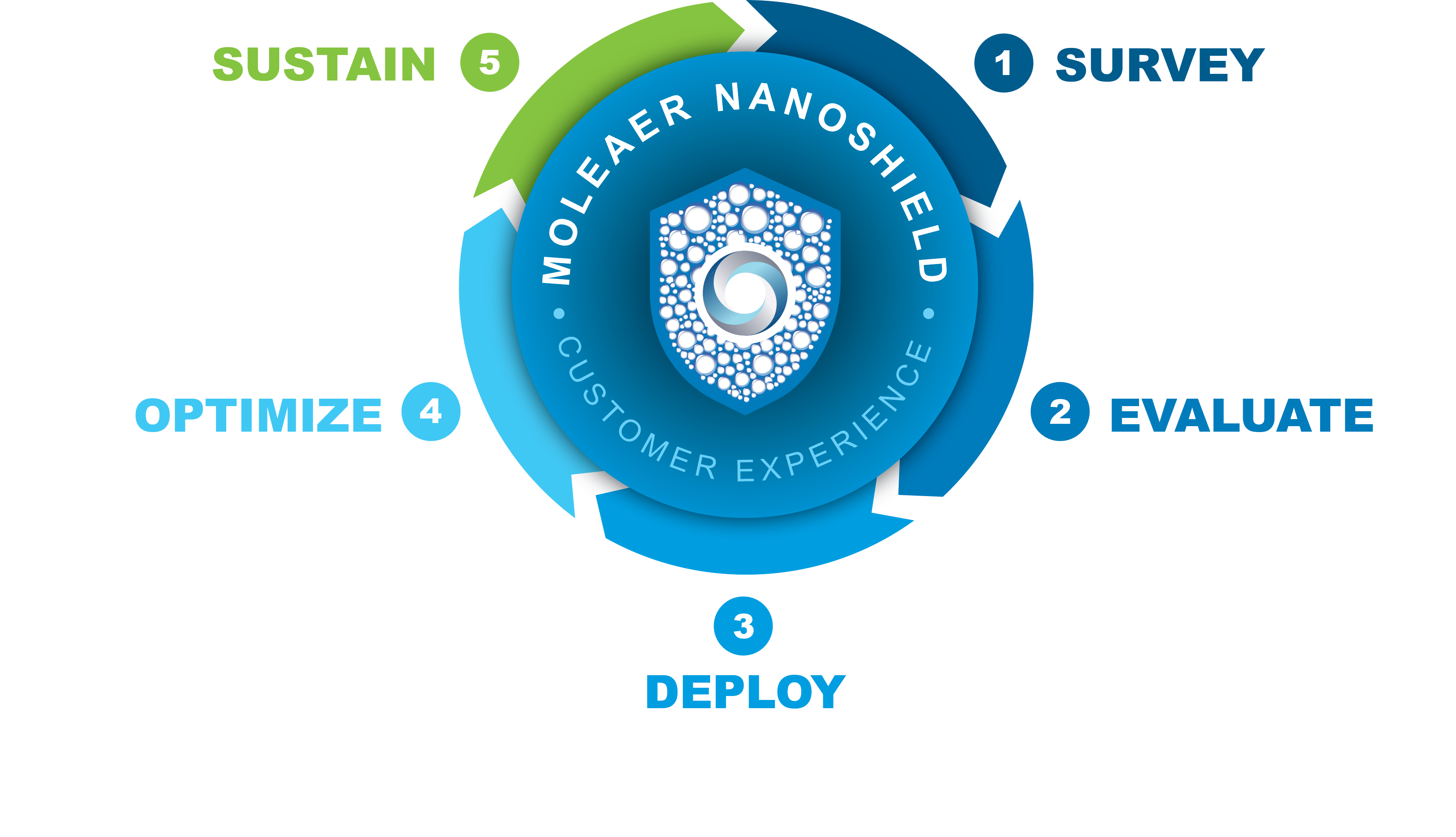

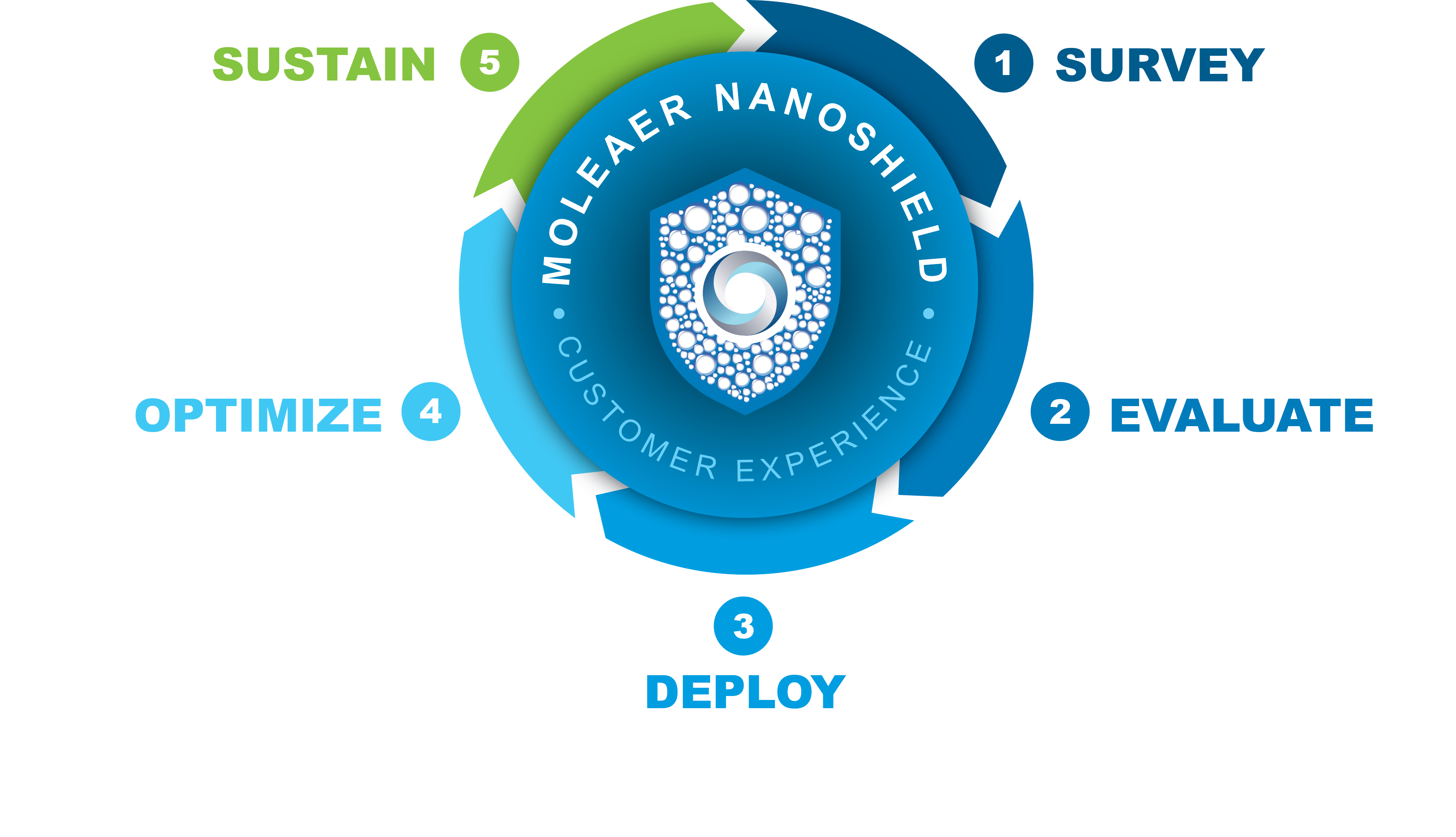

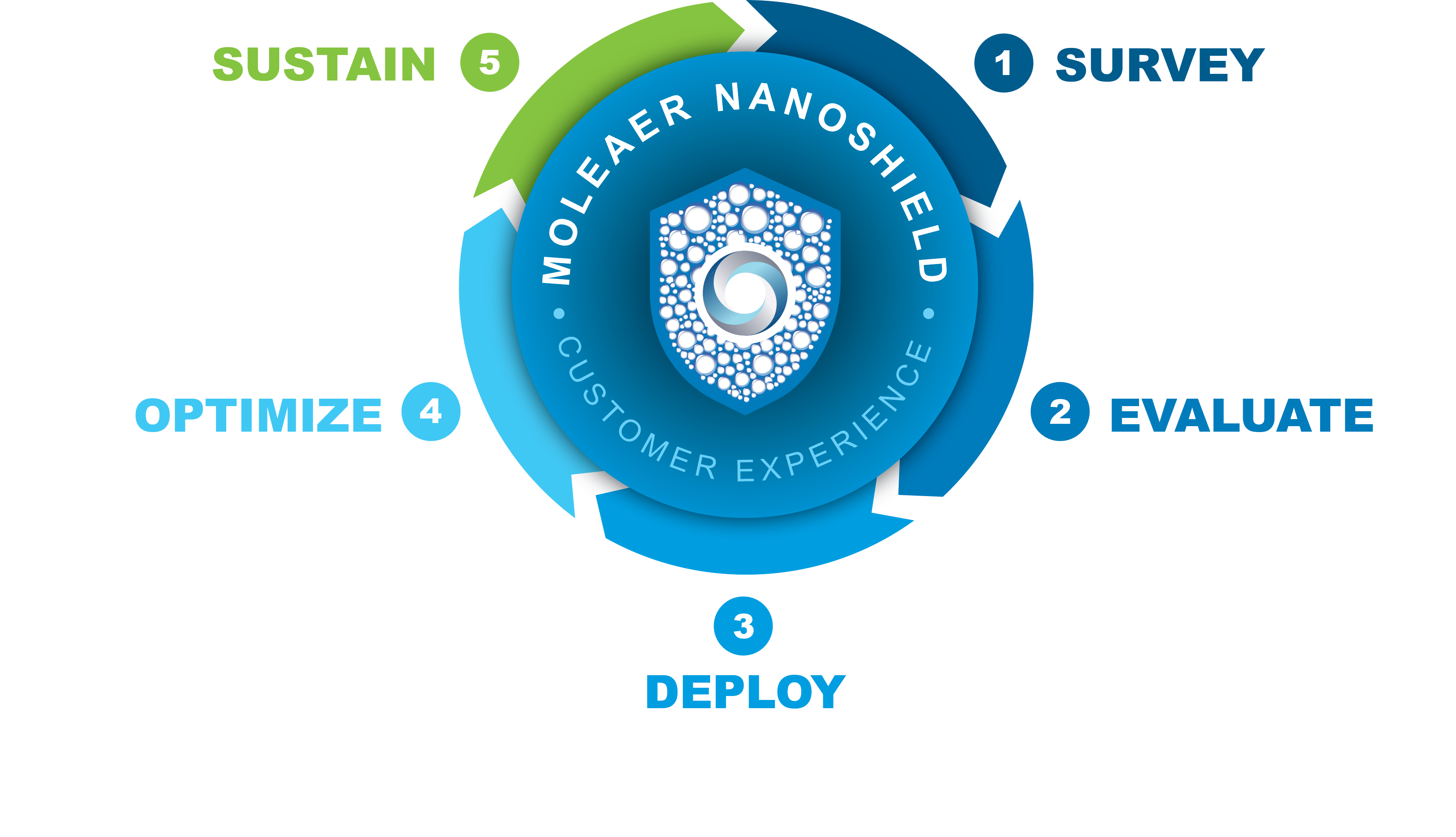

SURVEY

EVALUATE

DEPLOY

OPTIMIZE

SUSTAIN

INSTALLATION

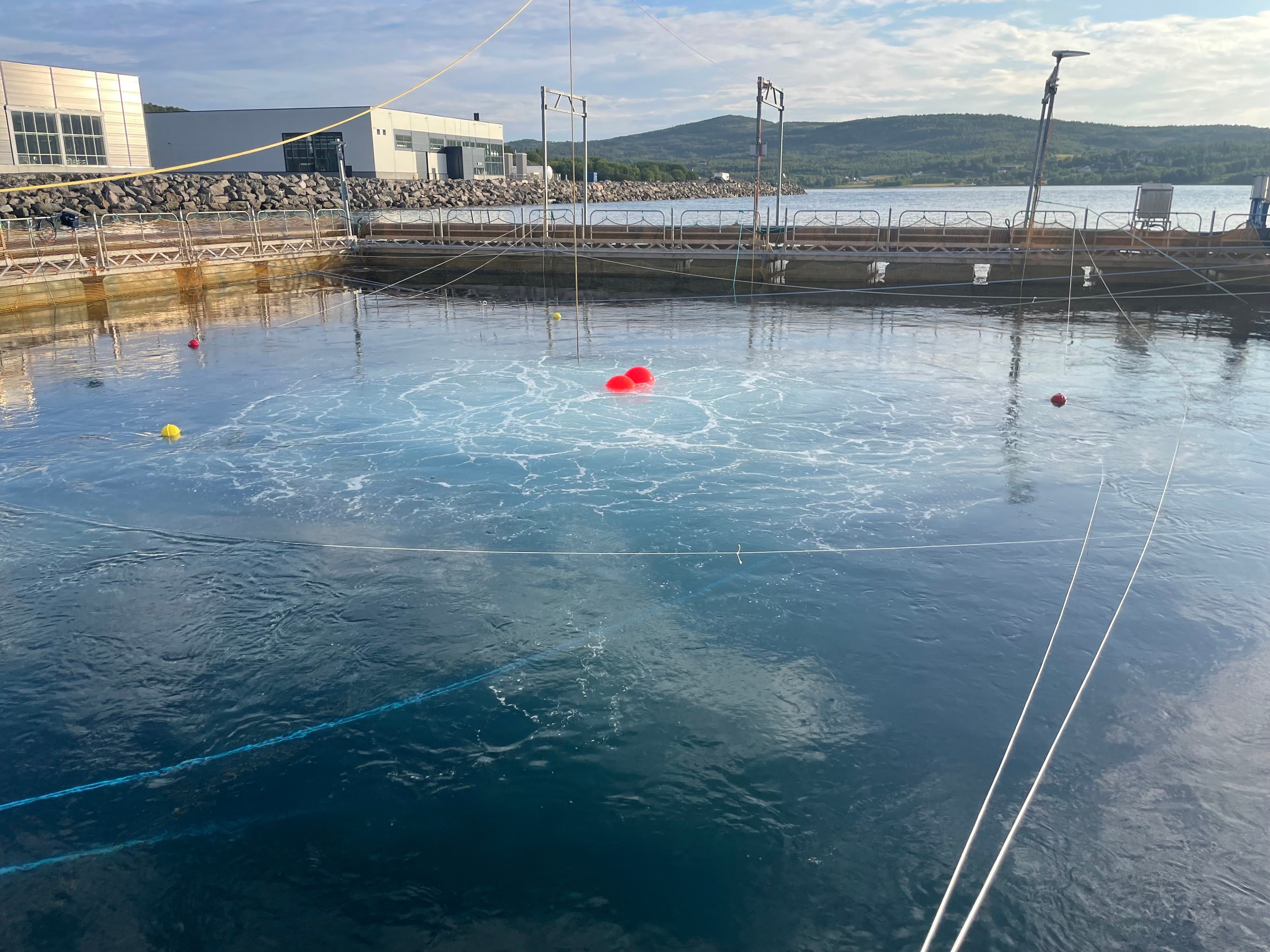

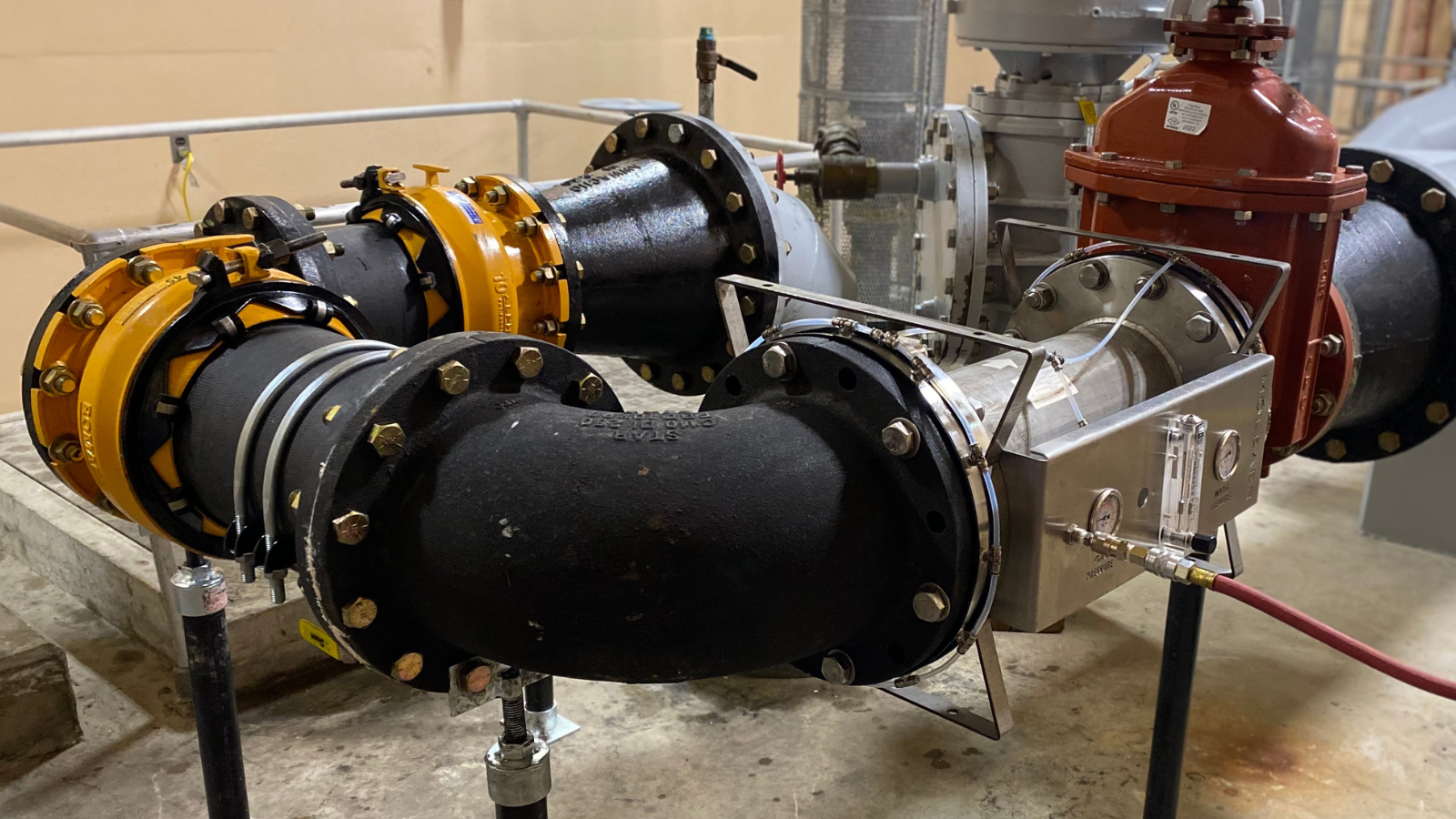

Purpose Built Nanobubble Solution for Your Needs

Simple integration with minimal maintenance and no downtime, Moleaer’s nanobubble systems help unlock your plant’s full potential within its existing footprint.

Case Studies

Real Results with NanoShield

City of Lodi WWTP

66%

lower effluent ammonia

41%

lower effluent BOD

Increased relative abundance of nitrogen removal bacteria

“In my 16 years at the city, I have never seen the plant recover as quickly from an ammonia spike as it did with Moleaer’s nanobubble system.”

Yucaipa Valley Water District’s Regional Water Recycling Facility (WRWRF)

20%

gain in BNR capacity

10%

increase in net ammonia removal

24%

decrease in blower energy/lb ammonia removed

Meister Cheese Company WWTP

100%

reduction in high-strength waste hauling

60%

increase in biogas generated

$54,000

chemical savings per year

"We’re planning to increase production by over 20 million pounds of cheese and whey products over the next 3 years since installing Moleaer equipment in our wastewater process. That includes avoiding $10 million in CAPEX improvements we would have needed to make. We recommend Moleaer’s system for other cheese manufacturers looking to increase their wastewater treatment capacity and production at the same time."

Connect with our team of wastewater experts

Solve problems at your treatment plant without costly upgrades with Moleaer NanoShield.

-1.png)

.png)

.png)